1. Introduction to Demand Driven Requirements Planning (DDMRP)

A system called Demand Driven Requirements Planning (DDMRP) helps businesses manage their inventory and production processes more efficiently by putting real demand signals—rather than just projections—front and center. DDMRP dynamically modifies inventory levels based on changes in real-time demand, in contrast to previous approaches that mostly rely on forecasting. This leads to shorter lead times, higher levels of customer service, and overall improved supply chain performance. This method offers a more flexible and adaptable technique to oversee supply chain activities in the erratic and fast-paced corporate world of today.

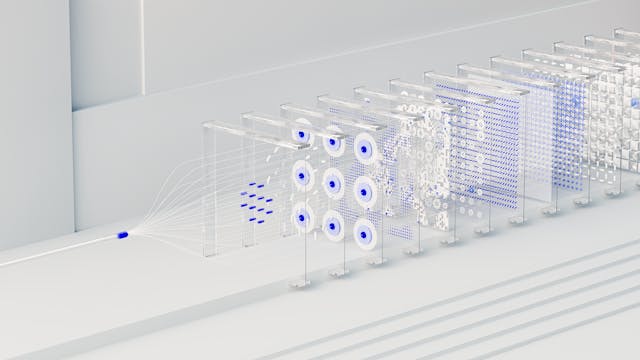

Decoupling inventory buffers—which are strategically positioned throughout the supply chain to absorb variability and guard against disruptions—is the fundamental idea behind DDMRP. These buffers help businesses maintain ideal stock levels without overstocking or understocking because they are computed based on the distinct demand characteristics, lead time, and unpredictability of each item. Organizations can increase their capacity to quickly satisfy consumer requests while reducing waste and expenses associated with surplus inventory by utilizing these dynamic buffers.

Demand-Driven Conditions Supply chain management has undergone a paradigm shift in planning, as demand-driven execution replaces forecast-driven planning as the primary focus. By matching inventory positioning to actual market demand trends, this methodology helps firms improve customer satisfaction, profitability, and operational efficiency. The subsequent segments of this blog series will go more deeply into the fundamental ideas of DDMRP and examine how companies may use this creative strategy to revolutionize supply chain operations.

2. The Basics of DDMRP: Key Concepts and Principles

A supply chain management technique called Demand Driven Requirements Planning (DDMRP) is centered on efficiently meeting customer demand. Fundamentally, DDMRP aims to align inventory levels with real demand, resulting in a supply chain that is more flexible and agile. Understanding that conventional forecasting techniques frequently result in inefficiencies and excess inventories is the fundamental idea of DDMRP.

A core tenet of DDMRP is the separation of the planning and execution phases. Companies may better match their inventory levels with changes in demand in real time by dividing these two factors, which will ultimately shorten lead times and increase overall responsiveness. The placement of buffer stocks strategically at key junctures in the supply chain to mitigate unpredictability and guarantee a steady flow of supplies is another essential component of DDMRP.

The concept of dynamically modifying stock levels in response to shifting demand signals rather than depending exclusively on static projections is at the heart of DDMRP. Businesses can become more robust to market uncertainty, demand-driven, and responsive with this dynamic approach. Businesses can improve customer happiness, reduce stockouts, and manage inventory levels by concentrating on actual consumption trends instead of projections.

3. Benefits of Implementing DDMRP in Supply Chain Management

Organizations can get a number of advantages by implementing Demand Driven Requirements Planning (DDMRP) in supply chain management. Better inventory management is one important benefit. By dynamically modifying inventory levels based on actual demand signals, DDMRP helps reduce excess inventory and stockouts while improving capital use and responsiveness to market changes.

Enhanced supply chain collaboration and visibility are two other major advantages of DDMRP. DDMRP encourages real-time information sharing among various stakeholders by concentrating on actual demand rather than forecasts, strengthening the bonds between suppliers, manufacturers, and distributors. More openness can result in quicker decisions and more effective operations.

Enhanced agility in adapting to shifts in consumer demand or market conditions is made possible by DDMRP. Organizations utilizing DDMRP can better manage demand variations, cut lead times, and enhance overall customer satisfaction because of its capacity to swiftly identify changes in demand patterns and modify replenishment tactics accordingly.

By avoiding overproduction and the costs associated with retaining extra inventory, DDMRP implementation can save costs. Organizations can achieve cost reductions throughout the supply chain and optimize operations by decreasing the need for rush orders or unnecessary safety stock and by aligning inventory levels with actual demand signals.

After putting everything above together, we can say that adopting Demand Driven Requirements Planning (DDMRP) in supply chain management has many advantages that can change the way businesses manage their inventory, work with partners, react quickly to changes in the market, improve operational agility, increase cost savings, and ultimately raise overall effectiveness and customer satisfaction throughout the supply chain ecosystem.

4. Case Studies: Real-life Examples of Successful DDMRP Implementation

Case studies offer priceless insights into how Demand Driven Requirements Planning (DDMRP) is actually applied in practice. Now let's look at some actual cases of DDMRP implementation gone right.

A manufacturing company had stockouts and excess inventories due to varying demand. Through the application of DDMRP concepts, their supply chain was optimized. They were able to significantly reduce lead times and increase on-time delivery by strategically placing buffers and improving demand visibility.

An further case study within the retail sector demonstrated the advantages of DDMRP in handling fluctuations in seasonal demand. This store increased customer happiness and overall profitability by minimizing overstock situations during quiet seasons and guaranteeing product availability during peaks through dynamic adjustments to inventory levels based on actual demand signals.

The adoption of DDMRP techniques resulted in a distribution company streamlining its operations. They decreased excess inventory expenditures and increased overall operational efficiency by modifying replenishment parameters dynamically and matching inventory levels to current market demands. Better cash flow management and increased market response were the outcomes of this.

The practical benefits of implementing DDMRP into supply chain management procedures are highlighted by these case studies. In today's competitive business world, the flexibility and adaptability provided by DDMRP allows organizations to react quickly to changing market dynamics, eventually improving customer service levels, maximizing inventory investment, and fostering sustainable growth.

5. How DDMRP Improves Inventory Management and Reduces Lead Times

For enterprises, Demand Driven Requirements Planning (DDMRP) can greatly improve inventory control and expedite lead times. With DDMRP, actual demand signals are the main focus instead of projections, as is the case with standard inventory management techniques. Through dynamic adjustments of inventory levels in response to current demand, businesses can minimize excess stock while maintaining product availability.

Decoupling the supply chain from fluctuations in demand is a crucial way that DDMRP enhances inventory management. To guard against variations, DDMRP employs planned inventory positioning and buffer sizing as opposed to responding to forecast errors or abrupt adjustments in demand. By taking a proactive stance, stockouts and overstock scenarios are reduced, and inventory levels are optimized across the supply chain.

DDMRP assists companies in efficiently allocating resources by using color-coded alerts such as green, yellow, and red zones to prioritize commodities based on real customer demand. Businesses may concentrate their attention where it's most required thanks to this segmentation, which shortens lead times and boosts overall operational effectiveness.

Using DDMRP can completely change how businesses handle their inventories and quickly adapt to market demands. Businesses can get a competitive edge in today's fast-paced market climate by using cutting-edge solutions to visualize supply chain dynamics and matching replenishment strategies with actual consumption trends.

6. Challenges and Pitfalls to Avoid When Adopting DDMRP

A company can reap great benefits from implementing Demand Driven Requirements Planning (DDMRP), but like with any new system, adoption comes with obstacles and potential hazards. Employee resistance to change, stemming from their familiarity with traditional MRP systems, is a prevalent obstacle. Comprehensive training and education about the advantages of DDMRP are crucial to reducing this.

Over-reliance on software solutions without a thorough comprehension of DDMRP's guiding principles is another common mistake. Before using software solutions to implement DDMRP, organizations must understand the approach and underlying ideas. Without this fundamental knowledge, businesses can find it difficult to properly handle problems that come up during implementation.

When moving to DDMRP, inaccurate or insufficient data can provide serious difficulties. For the system to be successful, lead time and demand forecast accuracy are critical. Businesses should make investments to raise the visibility and quality of their data in order to guarantee that DDMRP functions properly and produces the desired outcomes.

The effective implementation of DDMRP may be hampered by neglecting organizational alignment. Under the new planning framework, it is imperative that many departments within a company, including production, procurement, and sales, collaborate effectively. Information flow that is required for precise demand forecasting and planning might be impeded by siloed activities.

Finally, approaching DDMRP as a one-time exercise rather than an ongoing process is a major mistake that businesses should avoid. The long-term viability of DDMRP deployment depends on ongoing enhancement and optimization. It is essential to conduct regular reviews, updates, and modifications based on performance data to guarantee that DDMRP keeps up with the changing demands of the company in a changing market.

7. Implementing DDMRP Step by Step: A Practical Guide for Businesses

A number of crucial actions are involved in implementing Demand Driven Requirements Planning (DDMRP), which can assist companies in streamlining their inventory and supply chain management procedures. In order to determine which aspects of their current supply chain activities can profit from the introduction of DDMRP, organizations need first undertake a thorough examination of them. This entails evaluating lead times, order frequency, demand variations, and current inventory levels.

The DDMRP model must then be created with the particular requirements of the company in mind. This entails establishing strategic inventory buffers at different stages of the supply chain to guard against unpredictability and guarantee that client orders are fulfilled on time. Companies should also start working together with distributors and suppliers to better coordinate inventory management and enhance network visibility throughout the supply chain.

Businesses must put in place the required software tools and technologies to support the DDMRP model's effective execution after it has been defined. Purchasing inventory management software, demand forecasting tools, and enterprise resource planning (ERP) systems that function well with the DDMRP architecture may be necessary to do this.

Effective implementation of DDMRP requires staff training on best practices and concepts. Businesses can guarantee seamless adoption and alignment with new processes and workflows by providing staff with training on DDMRP's functionality and organizational benefits. Continuous monitoring and performance evaluation are necessary to assess the DDMRP implementation's efficacy over time.

After putting everything above into perspective, we can say that putting DDMRP into practice calls for a methodical strategy that includes careful analysis, strategic planning, technology integration, staff development, and ongoing improvement initiatives. Businesses can efficiently respond changing market needs by improving their supply chain's agility, reactivity, and overall efficiency by carefully adhering to these procedures.

8. The Future of Supply Chain Management with DDMRP

With an eye on supply chain management's future, Demand Driven Requirements Planning (DDMRP) is poised to transform conventional methods. DDMRP makes it possible for businesses to be more responsive, flexible, and agile in their operations by concentrating on real demand signals as opposed to projections. This change from a forecast-driven to a demand-driven approach permits greater resource utilization while also lowering the risks related to imprecise forecasts.

The capacity of DDMRP to dynamically modify inventory levels in response to changes in real-time demand is one of its primary features. Through the use of dynamic buffers and the decoupling of planning and execution processes, businesses may guarantee that the appropriate quantity of stock is available at all times. This proactive strategy lowers surplus inventory, minimizes stockouts, and raises customer satisfaction levels overall.

By giving all departments within a corporation a shared understanding of demand requirements, DDMRP encourages cooperation. Through the dismantling of departmental silos and the promotion of communication among sales, production, and procurement teams, companies may effectively coordinate their efforts to meet client expectations. This cooperative strategy improves relationships both inside and outside while also increasing operational efficiency.

Furthermore, as I mentioned previously, supply chain management using DDMRP has a bright future ahead of it for businesses hoping to maintain their competitiveness in the hectic business world of today. Adopting a demand-driven approach and utilizing sophisticated planning techniques can help firms become more responsive, cut expenses, and perform better all around. With the ever-changing landscape of technology and customer expectations, DDMRP offers businesses a strong platform on which to develop flexible and robust supply chains that can compete in an increasingly complicated market.

9. Comparison between Traditional MRP and DDMRP Systems

There are a number of significant distinctions between Demand Driven Requirements Planning (DDRP) and Traditional Material Requirements Planning (MRP) systems. MRP is a push-based approach that mostly depends on projections. In contrast, DDRP uses a pull-based strategy to guarantee that inventory levels are optimized and is motivated by real demand signals. In addition,

Inaccurate projections are a common problem for traditional MRP systems, which can result in overproduction or stockouts. By dynamically modifying inventory levels in response to changes in real-time demand, DDRP reduces this risk and increases businesses' flexibility and responsiveness to client needs.

While MRP usually necessitates regular manual intervention to make adjustments to production plans, DDMRP's advanced algorithms that examine demand fluctuation and buffer management substantially automate this process. Compared to typical MRP setups, this automation results in shorter lead times and higher inventory turnover rates in DDRP systems.

DDMRP excels in terms of scalability since it can quickly adjust to modifications in market conditions and demand patterns without requiring a significant reconfiguration of the entire system. Because traditional MRP systems have defined planning parameters and are not very flexible, they may find it difficult to keep up in such dynamic contexts.

10. Tools and Software for Effective Implementation of DDMRP

To optimize the benefits and streamline the process of Demand Driven Requirements Planning (DDMRP), the appropriate tools and technologies must be used. A number of software programs and tools have been developed expressly to support DDMRP concepts and assist businesses in effectively implementing this cutting-edge methodology.

A strong inventory management system that can dynamically modify inventory levels based on real demand signals is one crucial instrument for DDMRP deployment. In order to guarantee ideal inventory placement across the supply chain, these systems frequently include features like automated replenishment computations, real-time demand sensing, and order prioritizing.

DDMRP performance can be improved by using advanced planning and scheduling (APS) software, which offers thorough insight into material requirements, production schedules, and capacity restrictions. Organizations can better utilize their resources and increase the rates of on-time delivery by better aligning their production plans with real demand changes through the integration of APS with DDMRP procedures.

Real-time communication, information sharing, and collaboration amongst cross-functional teams on DDMRP activities can be facilitated via cloud-based collaboration systems. These systems improve the overall efficacy of DDMRP implementations by facilitating transparent data exchange, effective decision-making, and quick reactions to shifting market conditions.

Purchasing DDMRP-specific tools and software can greatly enhance supply chain efficiency, save lead times, save carrying costs for inventory, and ultimately increase customer satisfaction. Organizations may stay competitive and optimize their operations for the ever-changing market by properly utilizing these technologies.

11. Training and Certifications Available for Professionals in the Field of DDMRP

If professionals want to succeed in the field of Demand Driven Requirements Planning (DDMRP), they must obtain training and certifications. The acquisition of information and skills via specialized programs can substantially improve a person's comprehension of DDMRP methods and principles. A number of institutions provide certification and training programs designed to satisfy the requirements of supply chain experts who want to apply DDMRP efficiently.

Professionals in the DDMRP industry can obtain a renowned certification by completing the Demand Driven Planner (DDP) program. The goal of this certification is to give people the abilities and information required to implement demand-driven tactics in their workplaces. Participants will have a thorough understanding of DDMRP topics, such as capacity planning, demand fluctuation, and inventory management, after finishing this training.

DDMRP approaches are covered in-depth in advanced training workshops and seminars offered by organizations like the Demand Driven Institute (DDI). Through these workshops, professionals can network with colleagues, interact with industry experts, and acquire useful knowledge about applying DDMRP in real-world situations. In addition to improving skill sets, these training courses offer invaluable practical experience, which is essential for success in supply chain management.

Obtaining certifications like Certified Demand Driven Planner (CDDP) or Certified Demand Driven Leader (CDDL) might be beneficial for professionals who want to work in the DDMRP field. These credentials attest to a person's competence in implementing demand-driven concepts to enhance supply chain efficiency and spur corporate expansion. Professionals in the area of DDMRP show their dedication to ongoing education and professional growth by attaining these credentials.

In summary, for those who want to progress in their supply chain management professions, it is essential to invest in training and certifications connected to Demand Driven Requirements Planning. These educational opportunities give professionals the necessary abilities to successfully negotiate the intricacies of contemporary supply chains in addition to giving them a strong foundation in DDMRP ideas. Pros can establish themselves as valued assets in their businesses and promote sustainable growth by implementing DDMRP tactics effectively by remaining up to date with industry best practices and developing their expertise through specialized training.

12. QandA Session: Common Questions Answered about Demand Driven Requirements Planning

Q&A Session: Common Questions Answered about Demand Driven Requirements Planning

1. What is Demand Driven Requirements Planning (DDMRP)?

A supply chain planning and execution technique called Demand Driven Requirements Planning (DDMRP) focuses on building an adaptable supply chain that is driven by real customer demand. Dynamically altering replenishment decisions based on demand signals helps to improve overall supply chain performance, minimize lead times, and optimize inventory levels.

2. How does DDMRP differ from traditional MRP systems?

Distinctive from conventional Material Requirements Planning (MRP) systems, which mostly depend on projections and predetermined lead times, DDMRP leverages up-to-date demand information to initiate replenishment operations. With this dynamic strategy, businesses may decrease surplus inventory, enhance customer service, and respond more quickly to shifts in demand patterns.🤭

3. What are some benefits of implementing DDMRP?

Businesses can reap a number of advantages from implementing DDMRP, such as better inventory management through increased visibility and control over stock levels, shorter lead times as a result of quicker reaction to demand fluctuations, higher profitability through more efficient resource allocation, and higher customer satisfaction from better service levels.

4. How can a company transition to DDMRP from traditional planning methods?

Analyzing present processes, laying out supply chains, determining essential control points, establishing DDMRP buffers based on demand fluctuation, educating staff on new techniques, and progressively phase-out outdated systems while integrating the new strategy are all part of the transition to DDMRP.

5. Is it necessary for a company to have specific software or tools to implement DDMRP?

It is not technically necessary, however specialized software created for DDMRP can facilitate implementation and offer extensive analytics capabilities. Businesses can use spreadsheets or other simple tools to implement DDMRP principles at first, and then determine whether to invest in specialized software to further optimize their processes.

6. How does DDMRP help in managing supply chain disruptions like those seen during the COVID-19 pandemic?

DDMRP is an excellent tool for handling unforeseen supply chain disruptions because of its flexibility and emphasis on actual demand signals. DDMRP makes supply chains more resilient and responsive, enabling businesses to swiftly modify production and procurement choices in response to real market demands and weather tough times.

7. Can DDMRP be applied across different industries and company sizes?

Yes, DDMRP principles are applicable to a wide range of sectors and business sizes where controlling inventory levels in response to customer demand is essential. Enterprises across several sectors, including manufacturing, retail, distribution, and services, can reap advantages from the flexibility and efficacy that DDMRP provides in terms of streamlining their supply chains.